AAC Supply And Transport

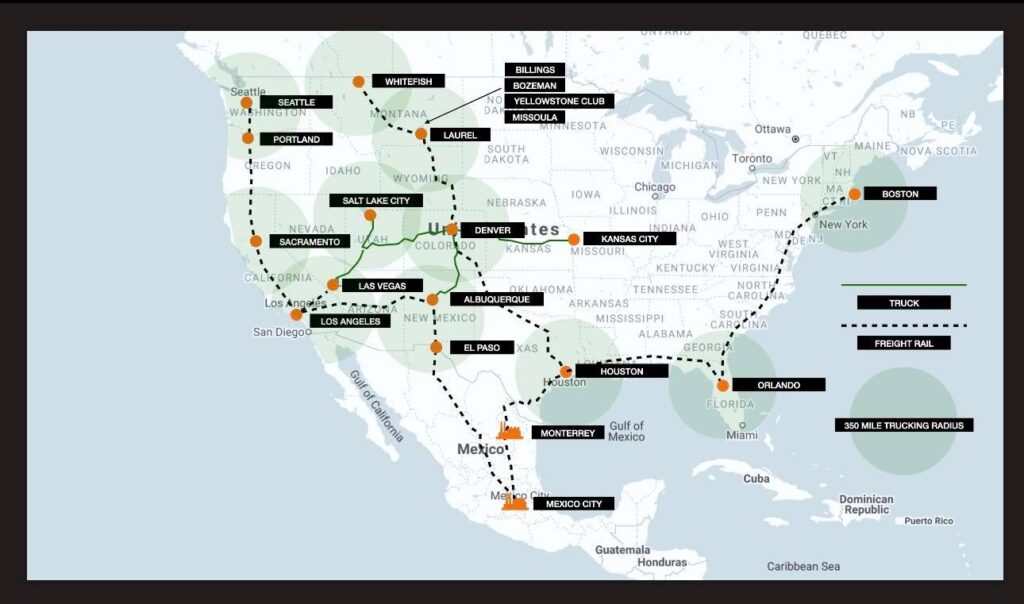

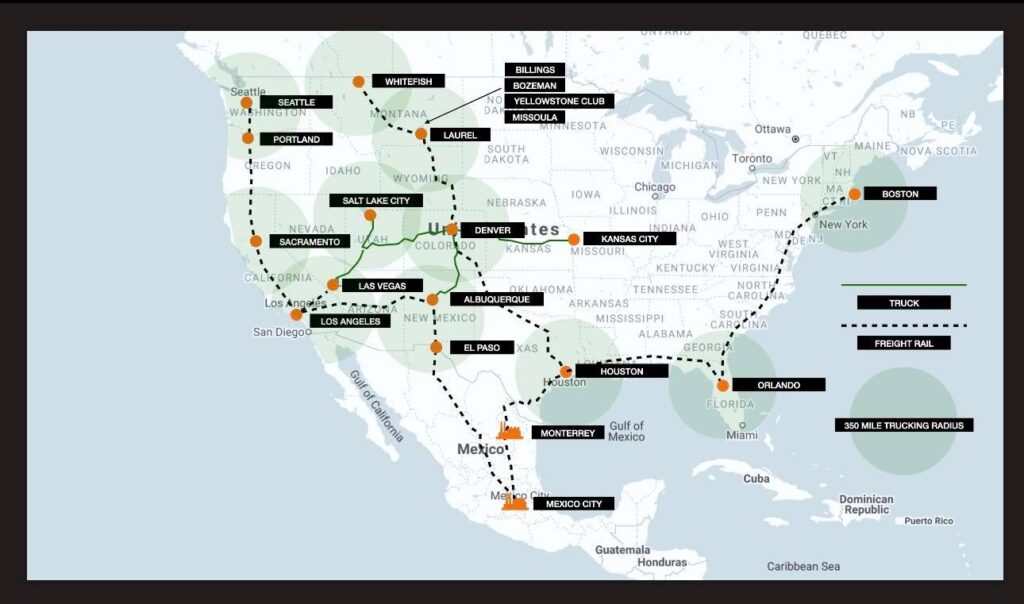

Scot Build US is able to supply your building site any where in the United States we have distribution lines all over.

Scot Build US is able to supply your building site any where in the United States we have distribution lines all over.